Explosion Proof vs. Intrinsically Safe

Why and when do you choose Explosion-Proof protection or Intrinsically Safe protection? The answer depends entirely on the intended purpose of the equipment: what is its desired outcome, and in what environment will it operate? And importantly, can these expectations coexist?

Choosing the Right Protection Method

The choice between Intrinsically Safe and Explosion-Proof often comes down to the balance between performance and safety. Intrinsically Safe design requires the equipment to operate with power levels low enough to prevent the risk of ignition. This is typically achieved by limiting voltage and current within a device to prevent electric arcs or temperatures from reaching the ignition point of combustible gases in the atmosphere. Intrinsically Safe designs are particularly suited for small, low-power devices such as handheld instruments, sensors, and communication tools, where functionality can be achieved without exceeding the strict limits on voltage and current. While this approach removes the chance of ignition, it also imposes significant constraints on the equipment’s capabilities. In situations where higher-power equipment is needed in a hazardous location, it’s difficult, if not impossible, to limit arcs and high operating temperatures. In such cases, Explosion-Proof designs are a suitable option, as they allow larger and more powerful equipment, such as motors, control panels, and lighting fixtures, to operate safely in hazardous environments.

The Principle Behind Intrinsic Safety

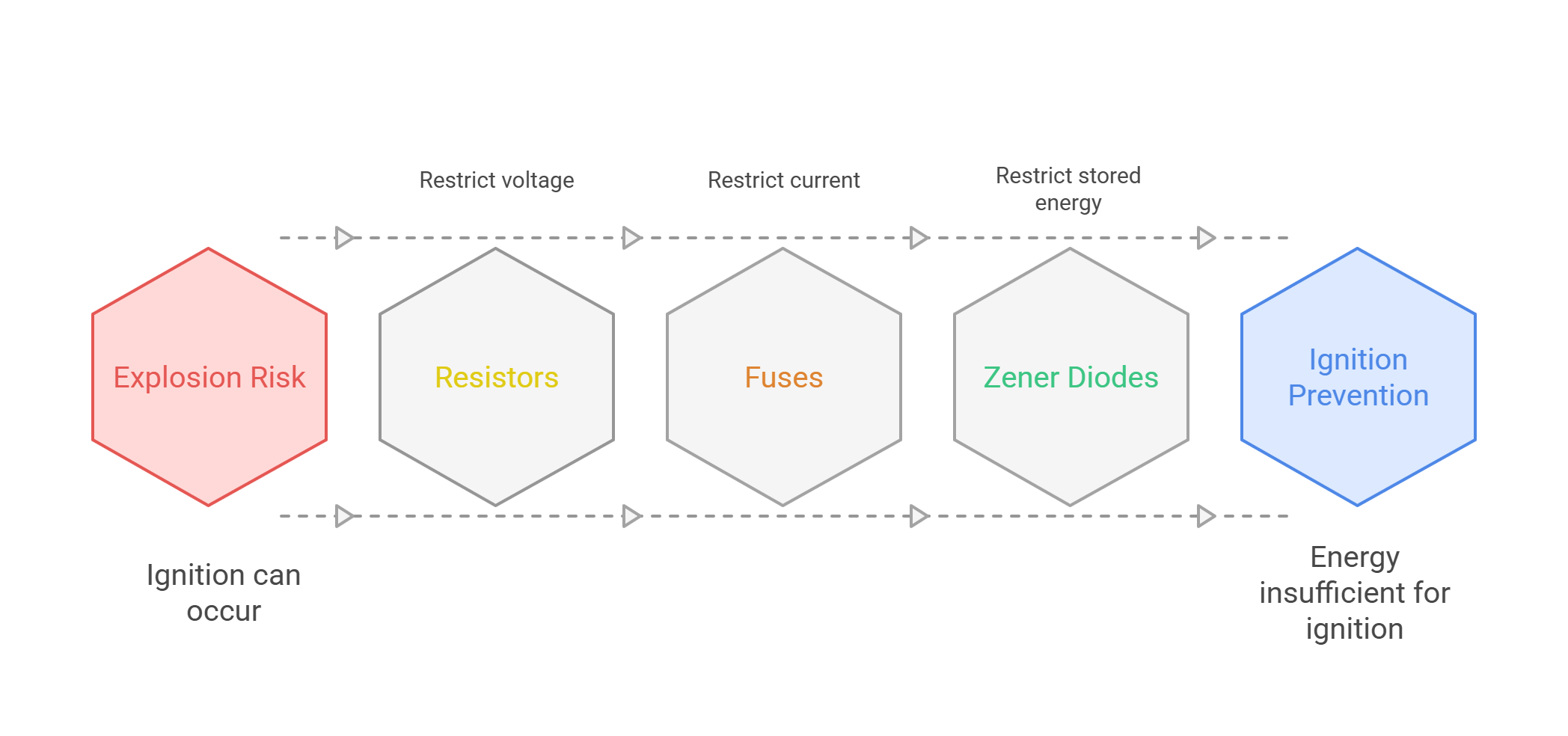

At the core of Intrinsic Safety is the principle of energy limitation. Rather than building barriers to contain an explosion, the design ensures that the ignition never occurs in the first place. This is achieved through components such as resistors, fuses, and zener diodes that restrict voltage, current, and stored energy to levels far below what is required to ignite flammable gases. Even if a short circuit, spark, or fault occurs within the device, the available energy is insufficient to create an ignition source. In this sense, Intrinsically Safe systems function like a ‘fire extinguisher built into the circuit’, removing one leg of the fire triangle (energy) so that combustion cannot start at all.

A Brief Insight into Explosion Proofing

With Explosion-Proof equipment, arcs and temperatures are permitted to exist. Therefore, an explosion may occur inside the equipment, but it must be contained and prevented from spreading to the surrounding combustible environment. Typically, this containment is achieved with a thick-walled housing made of aluminum or other suitable materials, secured with large bolts. The enclosure may close with a hinged door or a screw-on lid and can also include porous flame arresters. Regardless of the design, all feature one critical element: a flamepath.

For an explosion to propagate, it needs the same ingredients as a campfire: oxygen, fuel, and energy. In an explosion-proof enclosure with a door, the door seals against the thick walls, creating a broad surface that any internal explosion must propagate through. A porous flame arrestor, on the other hand, contains tiny pathways that allow air to seep through when under pressure. In both cases, heat from an ignition is absorbed into the arrestor or the walls of the enclosure as it squeezes through this pathway. Furthermore, the small volumes within these flamepaths are not sufficiently large for the flammable atmosphere components to mix effectively, preventing the proper ratio of ingredients for combustion. Whatever shape they take, flamepaths rob the explosion of the components required to continue propagating.

Explosion-proof measures have existed since the early 1900s, with formal regulations introduced in the 1920s. Although Intrinsically Safe measures were later developed as a more stringent level of safety, Explosion-Proof continues to be a widely used type of protection for equipment operated in Hazardous Locations.

Industry Applications

- Oil and Gas: Explosion-Proof housings are commonly used for pumps, compressors, and large electrical devices, while Intrinsically Safe protection is often applied to portable meters and monitoring instruments.

- Mining: Equipment in underground mines frequently relies on Intrinsically Safe systems due to the confined, high-risk environment.

- Chemical Processing: Explosion-Proof designs protect heavy-duty machinery, while Intrinsically Safe circuits are used for instrumentation and control systems.

Evolving Standards

Both protection methods are governed by strict international standards, including IEC, EN, CSA, UL, and more. While the fundamentals of Explosion-Proof technology have remained consistent for a century, advancements in materials, technologies, and design methods require continuous updates of existing standards or the development of new ones. Intrinsically Safe technologies also evolve, especially as industries demand more powerful handheld and wireless devices that still meet stringent safety limits.

The Bottom Line

Neither approach is universally “better” than the other. Instead, the correct choice depends on the type of equipment, the hazards present, and the operational needs. In some cases, a combination of both protections within a single system ensures optimal performance and compliance. Understanding these differences is critical for engineers, operators, and manufacturers of equipment operated in and developed for hazardous locations.