Hazardous Locations

Testing, Certification & Inspection for HazLoc equipment.

As an OSHA Nationally Recognized Testing Laboratory (NRTL), LabTest Certification provides manufacturers with Testing, Certification, & Unit Verification services for equipment installed and operated in potentially explosive (Ex) environments, for the North American (Canada and the USA), European (ATEX), United Kingdom (UKCA), and Global markets (IECEx).

As an accredited Testing & Certification body for Canada and U.S.A., an OSHA Nationally Recognized Testing Laboratory (NRTL), a recognized Notified Body for the European ATEX Directive, and a recognized member of the IECEx Scheme, LabTest is able to provide one single solution for product approvals for most global markets.

Equipment approved for Hazardous Locations is evaluated for compliance with industry published standards (IEC, EN, UL, CSA and etc.), to confirm that the equipment will not ignite a flammable gas, liquid, vapor or combustible dust.

What is Hazloc?

Also known by different names such as “Hazardous Areas”, “Ex Areas”, and “Explosive Atmospheres”, Hazloc relates to areas where flammable liquids, vapours, gases or combustible dusts are likely to occur in quantities sufficient to cause a fire or explosion.

What is “HazLoc Equipment (Ex Equipment)?

HazLoc Equipment refers to any electrical and non-electrical equipment that when installed in Hazardous Locations/Explosive Atmospheres, can create a spark or has enough energy to ignite a flammable gas, liquid, vapor, or combustible dust.

Global Market Access (GMA)

LabTest Certification assists manufacturers of Hazardous Locations equipment with product approvals for most international markets. Our accreditations to most IEC standards, but also to country-specific standards, will open the doors to the world for your business and products.

Canada | USA | Europe | UKCA | India PESO |Brazil INMETRO | Russia EAC and TR CU | Japan TIIS | China CCC | Korea KTL/KGS/KOSHA | Taiwan CNS | Saudi Arabia SASO | UAE ESMA/ECASEx | and more.

Product evaluation to CSA, UL, ISA, and FM Standards. Ordinary and Hazardous Locations standards. Classes/Divisions and Zones methodology.

Get your products to market faster when partnering directly with an accredited Notified Body. Testing, Certification, QAN audits, and Training from qualified experts with many years of industry experience.

Based on the project requirements, our network of field inspectors and partners can provide Unit Verification services across North America and overseas.

Our Hazardous Locations team comes with 100+ years of collective experience. Haz-Loc members participate in Ex Technical committees, for example TC 31, USNC/IECEx, and ICHL.

LabTest Certification is your Accredited ISO 17065 Certification Body, ISO 17025 Testing Laboratory, ISO 17020 Inspection Body, and ATEX Notified Body for all your HazLoc Testing and Certification needs.

Ex Component Approval

When a product is approved as an equipment, it must meet all applicable requirements as per the applicable standards, according to the Methods of Protection involved in the Ex design. However, when the approval is for a component that is eventually intended to be a part of an Ex equipment, only limited amount of testing is conducted.

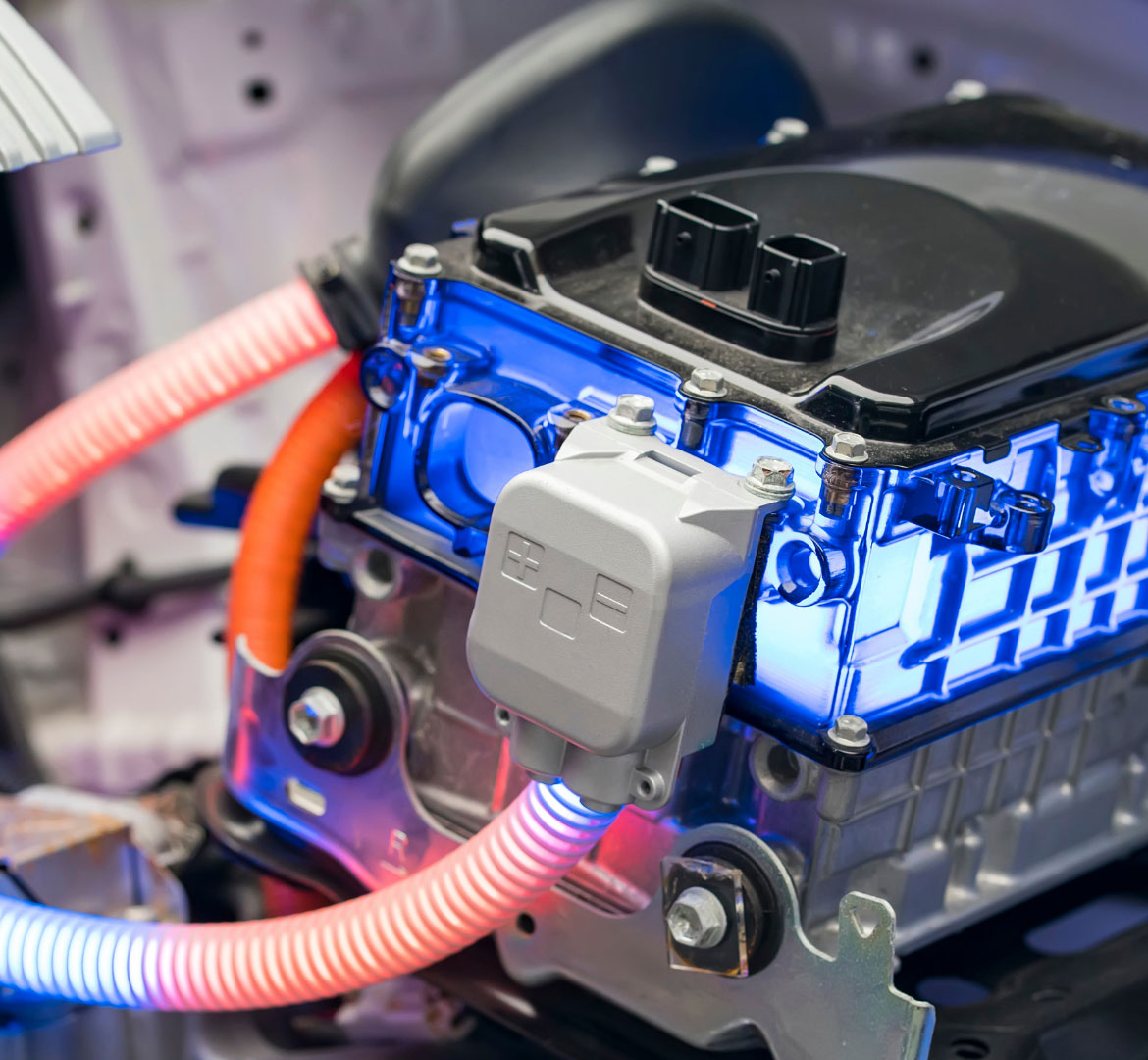

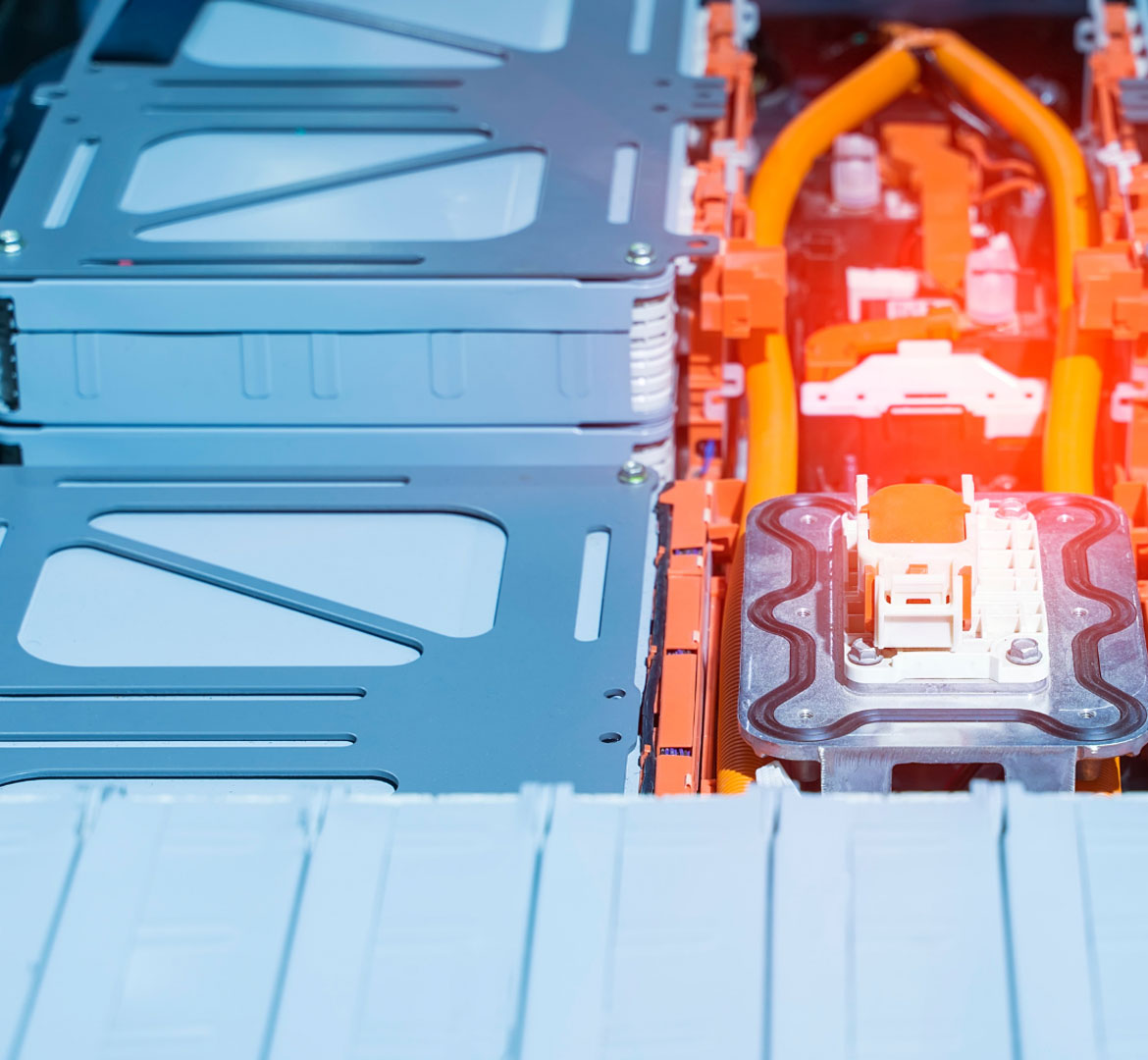

Hazardous Locations & Batteries

North America (Division markings)

For North American (Division) evaluation, it is critical to start with a battery that is recognized/certified/ component certified to ordinary locations requirements first. The ordinary locations certification standard will depend on the type of battery, compartment, and the type of constructions. When it comes to the Hazloc considerations, these will include venting considerations for Division 1 enclosures housing batteries and evaluation for possible ignition at short circuit current for Division 2. Battery and its protection circuit should be ensuring that power levels are below non-incendive curves as prescribed in the standards. In addition, operator replacement or recharging, during normal operation, are all arcing and sparking activities that need closer evaluation in Division 2 environments. Suitable protections, markings, and warnings are prescribed, in such cases, for batteries and charging circuits.

IECEx & ATEX (Zone markings)

When it comes to IECEx & ATEX, and Zone evaluations, it is still a fairly good practice to start off with a battery that is recognized or listed to some ordinary locations requirement, for electrical safety. The rest of the evaluation will depend on the kind of HazLoc standards that will be applied. For instance, flameproof standards (IEC/EN/UL/CSA 60079-1) evaluations include the ability of the battery to be charged within flameproof enclosures, polarity reversals, and battery compositions (covered by Annex E). As a practice, vented batteries are not allowed in flameproof enclosures. Increased safety standards (IEC/EN/UL/CSA 60079-7) evaluations take into account the capacity of the battery (25AH) to determine the evaluation route. Battery charging, sealing, encapsulation, valve regulation, etc. all become critical. Intrinsic safety standards and evaluations (IEC/EN/UL/CSA 60079-11) take into account the battery protection circuit, infallibility, electrolyte leakage, short circuit test, open circuit test, spark ignition test under fault, and rupture pressure of battery containers.

Unit Verification

Unit Verification is a practical approach for the approval of products manufactured in limited quantities. A quick solution for faster time to market for hazardous locations equipment. Our global network of field inspectors are able to evaluate your products anywhere across the globe.

Preliminary Design Review

PDR is a great way to find out if the product you’re designing is on the right track with the requirements of the applicable standards. PDR is mostly a documentation review which often doesn’t require a product sample. This review helps to identify potential red flags in the design, before too much time and money are invested.

Testimonials

We’ve been very impressed with Mr. Sidhu’s replies to our emails, at non-routine hours, as we work in different time zones. It indicates that he cares and that he is committed to the process. We also always enjoy working with Jason Forselius, LabTest’s Certification Field Rep, and learn from his experience, knowledge, and professionalism.

I heard about Labtest from a colleague who recommended them. They explained which standards applied to our products and how the audit process worked. Staff had extensive knowledge pertaining to the application of the correct standards for testing each model. Working with Labtest was very helpful in gaining a better understanding of applicable standards. Our company is now ATEX and IECEx certified to build approved products. Thank you Labtest!

I would recommend LabTest for your Testing and Certification needs. Our project went well and was completed on time and within budget. It was great to have a team of test engineers who listen to your requests. Although I have not personally met most of the engineers, I feel like I know them.

Working with LabTest Certification was great. We appreciated the quick turnaround on the quote and the detailed conversations and valuable input that Gursher Sidhu, Hazloc Account Manager, provided during the process. The competitive pricing and their understanding of our needs guided us in making a quick decision on how to prepare our product for certification.

This past year, Surepoint headed into a new direction for its Panel Shop in regards to our panel Class I, Div. 2 certification, as some standards had changed. We partnered with LabTest to serve our clients with a superior product, quicker turnaround times, and a reasonable price. LabTest was very professional and very detailed in their work and made it fairly easy to accomplish our business goal. Our company is happy to partner with LabTest for our testing and certification needs and looks forward to working with them to maintain our current certification and any new certifications that are required.