One Window, Many Pressures: Why NAFS Ratings Mean More Than a Label

For most building components, there’s a clear line between design, construction, and performance. A beam holds weight, a pipe carries water, insulation keeps heat where it belongs.

Windows and doors don’t follow that pattern.

They must seal, ventilate, resist wind, shed water, transfer force, remain stable under fluctuating loads, and still open with one hand on a cold morning. That complexity is why the North American Fenestration Standard: NAFS / AAMA/WDMA/CSA 101/I.S.2/A440 evaluates fenestration products differently than almost anything else in a building.

NAFS doesn’t ask “Does it work?” It asks “Does it keep working when the variables change?”

And those variables are exactly what complicate fenestration testing.

Pressure Isn’t Just One Direction

Air infiltration seems straightforward until you test it. Under NAFS, operable products aren’t only evaluated by how much air leaks into a building, but how much escapes as well. Positive and negative pressures tell different stories, and in certain climates, the difference matters more than people realize.

Wind gusts push air inward. Stack effect pulls air outward. A unit that performs admirably under one condition can perform very differently under the other. And once installed, a building experiences both, sometimes in the same hour.

It’s a subtle point embedded inside AAMA/WDMA/CSA 101/I.S.2/A440, but it’s one of the details that separates a compliant product on paper from a comfortable space in practice.

Water Doesn’t Behave Like Air and It Never Forgives Bad Design

The same pattern emerges when evaluating water penetration. Laboratory testing per ASTM E547 and ASTM E331, as referenced in NAFS, is controlled, repeatable, and precise. But it mimics a real threat: wind-driven moisture that doesn’t politely arrive in a vertical plane.

Water takes the path of least resistance through imperfect seals, at discontinuities, where panels meet frames, or where hardware interrupts continuity. A few millimeters of additional deflection under uniform load measured according to ASTM E330 can open pathways that didn’t exist moments earlier.

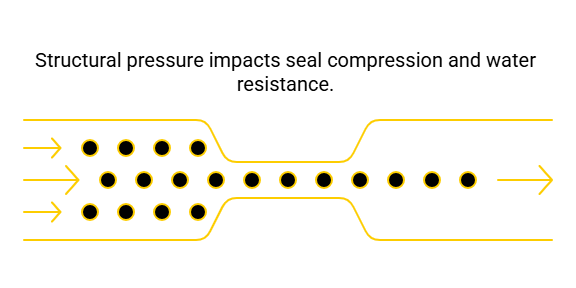

This is why NAFS doesn’t evaluate air, water, and structure separately. They form a loop: structural pressure influences seal compression, which affects water resistance, which shapes infiltration.

And a test sequence reveals how well a product manages that chain reaction.

The Hidden Variable: How It Feels to Operate

One of the most overlooked components of performance is the one that seems most subjective: effort.

Required operating force isn’t just a usability measure, it influences air and water integrity. Weatherstripping that seals aggressively may increase resistance to climate forces but makes opening and closing more difficult. Hardware adjustments intended to smooth operation may relax contact points that matter under pressure.

NAFS balances these competing demands within its Performance Classes – R, LC, CW, and AW, reflecting where a product is expected to live and what forces it must endure over time.

That’s why a single window design can fall into different performance categories depending on glazing, hardware, size, or configuration.

Size Isn’t Cosmetic, It’s Structural

One of the biggest surprises for new manufacturers is how size dictates outcome. A product that qualifies comfortably at one dimension may need to be tested again or redesigned as it grows. The structural stresses used to evaluate design pressure aren’t scaled proportionally. They increase faster than most people expect.

A small shift in height or width alters:

- how sash members bend,

- how load transfers through a frame,

- and how hardware tolerances perform at their limits.

That is why NAFS doesn’t certify a “model name.” It certifies a tested construction in a tested configuration, under stresses defined by the standard not by catalog assumptions.

What the Label Really Means

When a product earns its NAFS designation, it’s more than compliance. It signals that the interaction of materials, geometry, seals, hardware, and fabrication tolerances has held together under pressure, water, and load, and still functions as intended.

It reflects AAMA/WDMA/CSA 101/I.S.2/A440, applied through:

- ASTM E283 (air leakage)

- ASTM E547 / E331 (water penetration)

- ASTM E330 (structural load)

But most importantly, it reflects a recognition that windows and doors are not individual parts; they are systems disguised as single products.

Every decision from sash thickness to hinge choice is connected.

And when those decisions hold together under testing pressure, the building gains something invisible but essential: confidence.

The Takeaway

NAFS isn’t just a standard. It’s a way of acknowledging how complicated performance becomes when wind, water, air movement, pressure changes, and user expectations collide at one vulnerable opening in a wall.

That’s why pass/fail doesn’t tell the full story. The label does because it captures every challenge the product stood up to along the way.