IP65 or IP54: The Difference and What Industrial Manufacturers Need to Know

Do you need clarification about the difference between IP65 and IP54 ratings in industrial manufacturing? Let us be your Google for the day. This article will explain these (sometimes confusing) ratings and why they are crucial for industrial manufacturers. IP Rating Testing, also known as IP Test, classifies the ingress protection from solid objects, dust, and liquids provided by electrical equipment and enclosures. We’ll explore each rating in detail and compare them. Let’s learn about the importance of Ingress Protection (IP) ratings in manufacturing!

Key Takeaways

- IP65 offers enhanced protection against dust compared to IP54.

- IP65 can provide robust waterproof features.

- IP65 can withstand low-pressure water jets from any direction.

- IP65 is ideal for harsh environments.

Unpacking the Meaning of IP Ratings

You’re probably wondering what IP ratings actually mean, so let’s unpack that for you.

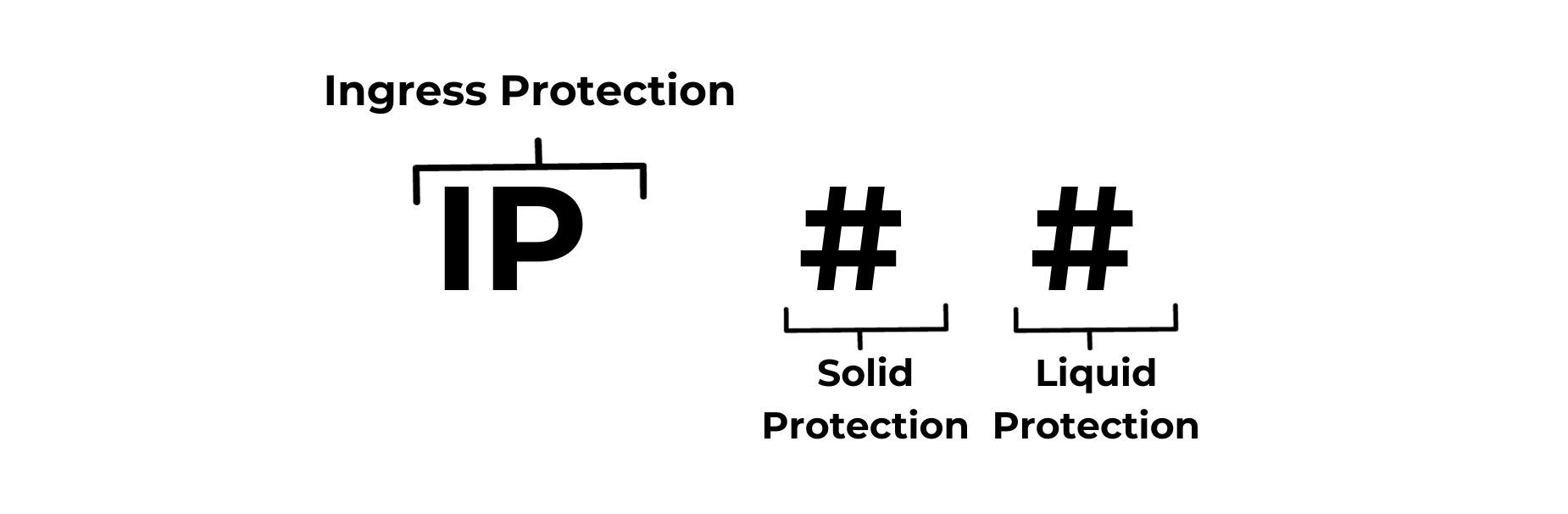

Originating from European Standards EN 60529, Ingress Protection (IP) ratings provide an international standard for defining ingress protection levels.

According to the International Electrotechnical Commission, the IP code consists of two digits that indicate the degree of protection:

- The first digit rates the protection from solid object/dust ingress, ranging from 0 (no protection) to 6 (no dust ingress)

- The second digital rates the enclosure’s protection from liquids, from 0 (no protection) to 9 (high-pressure hot water from different angles)

IPX Ratings Table

| IPX Rating | Description |

|---|---|

| IPX0 | No protection at all |

| IPX1 | Protection against water falling vertically |

| IPX2 | Protection against water falling vertically when tilted up to 15 degrees |

| IPX3 | Protection against water falling as a spray up to 60 degrees from vertical |

| IPX4 | Protection against water splashing from any direction |

| IPX5 | Protection against water jets from any direction |

| IPX6 | Protection against powerful water jets from any direction |

| IPX7 | Protection against temporary immersion in water up to 1 meter depth |

| IPX8 | Protection against continuous immersion in water beyond 1 meter depth |

Higher numbers signify increased levels of protection, though they don’t necessarily mean universal superiority. The ratings offer transparency for selecting enclosures based on specific needs.

The Specifics of IP54 and Its Applications

| Stage | Key Elements | Outcome |

|---|---|---|

| Sample Requirements | Defined by class, division, group, temperature rating | Suitable samples for testing |

| Documentation Process | Technical guidelines for design, markings, installation, user manual | Comprehensive documentation package |

| Testing Procedures | Rigorous evaluation against CSA, IEC, EN, UL standards and more | Compliance validation |

Delving Into the Details of IP65

IP65 offers enhanced protection against dust and water compared to IP54, which allows you to use your electronics in more challenging environments without worrying about damage.

IP65 Advantages

- Enhanced Dust Resistance: Unlike IP54, IP65 completely prevents dust ingress.

- Waterproof Rating: Withstanding low-pressure water jets from any direction.

IP65 Limitations

- Not suitable for long-term submersion or high-pressure water.

With these features, we see increased usage of IP65 in electronics, as they offer a higher level of security against environmental hazards.

Comparing and Contrasting IP54 and IP65

In comparing and contrasting these two standards, it's clear that each has its unique benefits and limitations.| Factor | IP54 Rating | IP65 Rating |

|---|---|---|

| Dust Protection | Limited | Superior |

| Water Resistance | Moderate | Excellent |

| Cost | Lower | Higher |

| Maintenance Requirements | Standard | Increased |

When choosing an IP rating for your industrial equipment, consider these factors to match the rating with the specific needs of your environment and equipment rather than viewing one rating as inherently better or more desirable than the other. Your decision should be cost-effective and prioritize product longevity, keeping in mind that the rating selection is neither universally better nor worse but tailored to your specific requirements.

Implementing the Appropriate IP Rating in Industrial Manufacturing

We recommend that you carefully evaluate the environment and specific conditions of your manufacturing process before deciding on the appropriate protection rating for your equipment. Consider these factors:

- Rating Implications: The difference between IP54 and IP65 could impact the longevity of your equipment.

- Safety Measures: Protective casings can safeguard against dust, water, and physical harm.

- Maintenance Considerations: Regular upkeep can affect productivity and cost factors.

We’ve got a responsibility to protect both our staff and our tools. It’s all about freedom: freedom from unnecessary risks, unplanned downtime, and unexpected expenses. Getting the proper IP rating isn’t just a technical decision; it’s an investment in peace of mind for us all in this unpredictable world we navigate daily.

Frequently Asked Questions

How Does the Cost Differ Between IP54 and IP65 Rated Equipment?

Our cost evaluation found IP65-rated equipment generally slightly more expensive than IP54 due to the time and set-up involved with the test. Budget considerations and market analysis reveal the economic impact of this pricing strategy.

Are There Any Specific Industries That Prefer IP54 Over IP65, or Vice Versa?

We’ve seen that industries with harsher environments lean towards IP65 for its superior protection, while those needing cost efficiency often favour IP54. It’s a comparative analysis based on industry-specific needs and rating selection factors.

What Are Some Common Challenges Manufacturers Face When Implementing IP Ratings in Their Products?

We often grapple with rating misconceptions, understanding protection levels, ensuring product durability, overcoming implementation barriers, and communicating rating importance. Navigating these challenges is crucial for successfully integrating IP ratings into products.

Can the IP Rating of a Device Be Upgraded After Its Production?

Yes, but it takes work. You might face retrofitting challenges that could impact quality. Upgrade feasibility and rating implications require careful consideration in post-production enhancements.

For any questions about Ingress Protection Ratings or to schedule an IP Test, please contact us at info@labtestcert.com.