The real challenge in Respirator Testing

We hear on the news that there are shortages of respirators for the front-line health care workers. But why do we all not deserve the same amount of safety?

Masks can be annoying to wear, give you an itchy nose, make it hard to breathe, and cause regrettable mask-acne! So why wear them? For our safety, and to help slow down the spread of the COVID- 19 virus. We put ourselves through this to try and help, but we are still buying masks that have not been tested, thus giving us a false sense of security when wearing them.

Understanding Protection Levels

N95 masks got their “name” from the ‘N’, signifying that the mask is ‘Non-resistant to oil’ and the proceeding number indicating the minimum efficiency of the mask (95%). For this type of mask, less than 5% of particles can pass through the mask.

Similar standards exist globally:

-

KN95 (China)

-

FFP2 (EU)

-

KF94 (Korea)

The Particle Size Paradox

Particle scientists have analyzed the behaviour of particle filtering and have found that the best particle size for respirator testing is about 75 nm, or 75 millionths of one millimetre.

Interestingly, particles smaller than that move around so much just from their own heat that (compared to larger particles) they are more likely to collide with a filter fibre and get stuck. Particles smaller than 75 nm are also easier to catch with electrostatic filtering – a technique used in many modern facemasks.

Testing Complexities: More Than Meets the Eye

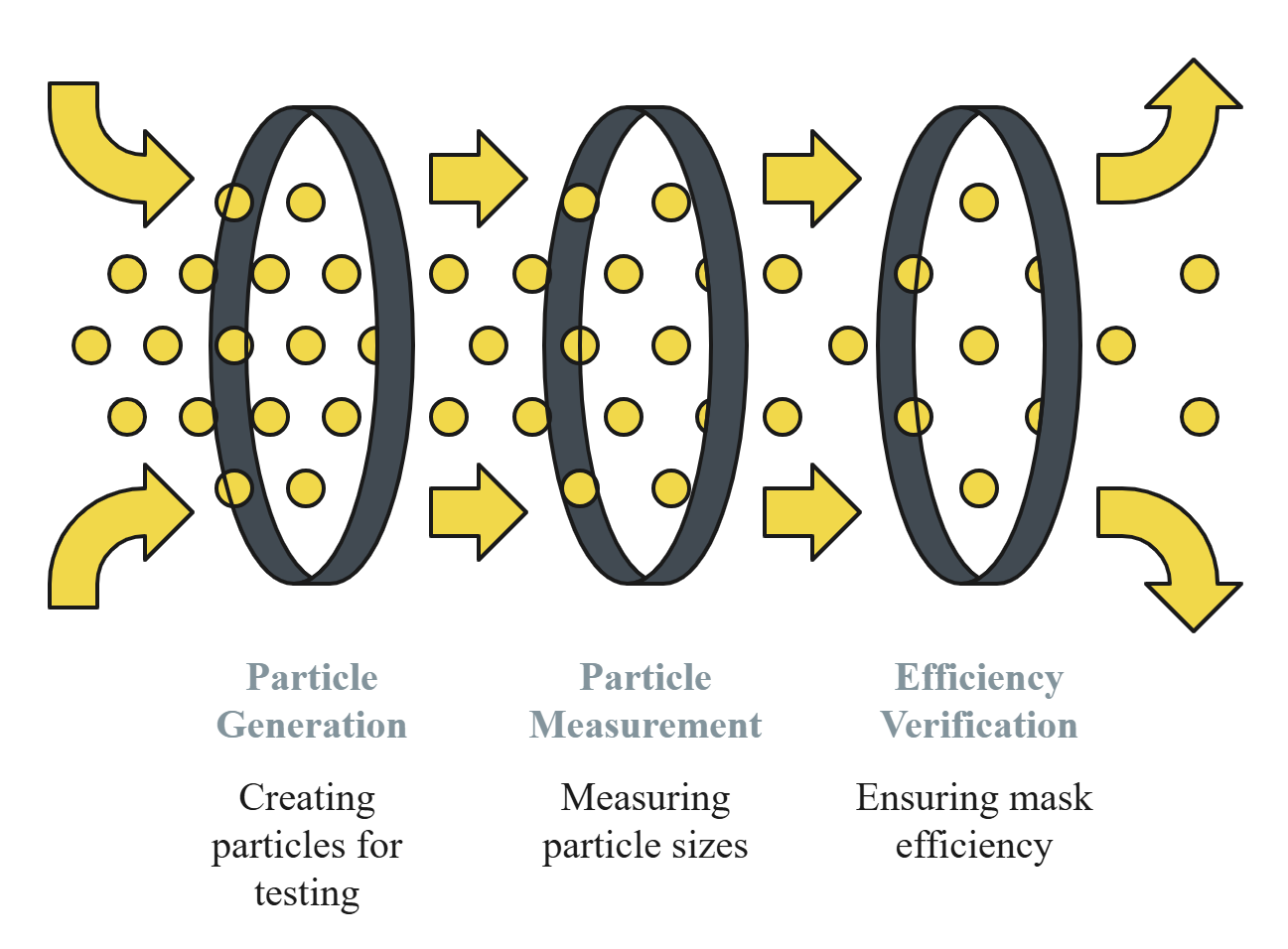

The real challenge in respirator testing is to generate the correct particles for testing and measuring the particles that pass through the mask. Generating the salt crystals involves creating a special saltwater mist and drying out the tiny mist droplets in a particular way.

Generating consistent 75nm salt particles requires precision:

-

A precisely controlled sodium chloride aerosol

-

Relative humidity maintained at 50±10%

-

Temperature-stabilized environments (25°C±5°C)

-

Drying chambers to eliminate moisture variability

The process is very sensitive, requiring a lot of attention to detail to keep the conditions in the right range.

Measurement Challenges

Keeping particles in the right range is very important, since larger or smaller particles will tend to get captured more easily by the filter, making it appear better, in the test results, than it really is. To verify that the particles remain in the right range throughout the testing process, it is important to measure them somehow.

Validating particle size distribution demands specialized instrumentation:

-

Scanning Mobility Particle Sizers (SMPS): Classify particles by electrical mobility

-

Condensation Particle Counters (CPCs): Magnify particles via alcohol vapour for detection

-

Laser photometers: Measure light scattering to determine concentration

Measuring the sizes of these tiny particles is another big challenge for laboratories, because 75 nm is such a small size that objects that size cannot be seen, even with a world-class optical microscope.

This is because light waves themselves are closer to 500 nm in size, and do not interact in any usual way with the particles.

To address this issue, engineers have invented a variety of special tools and measurement devices that can pick out particles of different sizes and even count them!

Why Accuracy Matters

Even minor deviations skew results significantly:

-

Larger particles (>300nm) get trapped mechanically

-

Smaller particles (<40nm) bind electrostatically

-

A 10% size error can show 20% better filtration than actual performance

This picking and counting can be a complicated process on its own but, in the end, is the most accurate known way to ensure the efficiency of masks.

Beyond Filtration: Critical Supplemental Tests

Certification requires additional evaluations:

-

Fit testing: Measures leakage around seals (quantitative/qualitative methods)

-

Breathing resistance: Evaluates airflow pressure differentials

-

Flammability testing: Assesses reaction to ignition sources

-

Structural integrity: Validates strap strength and clasp durability

The Human Factor in Laboratory Testing

Maintaining test consistency requires:

-

ISO 17025 accredited procedures

-

Continuous calibration of aerosol generators

-

Statistical confidence intervals for particle counts

-

Negative control baselines to eliminate environmental contaminants

Consequences of Inadequate Testing

Untested respirators risk:

-

Hospital-acquired infections in healthcare settings

-

Workplace exposure for industrial workers

-

Community transmission during outbreaks

-

Legal liabilities for manufacturers

The Path to Reliable Protection

Rigorous certification isn’t just regulatory compliance; it’s an ethical responsibility. As new variants emerge and airborne threats evolve, third-party validation remains the gold standard for respiratory safety. Manufacturers investing in proper testing don’t just meet standards; they build trust with end-users who bet their lives on these devices every day.