Are You An Off-Roading Lover? This Is Why Vibration Testing Matters!

Are You An Off-Roading Lover? This Is Why Vibration Testing Matters!

Picture this: it’s Saturday morning, and you’re taking your 4×4 Jeep out for a ride. You head into the backcountry, navigating rocky trails, steep inclines, and the kind of terrain that makes your teeth chatter. It’s the perfect weekend for any off-road enthusiast.

But while you’re having fun behind the wheel, your Jeep’s electronics are taking a beating.

Electronics Under Pressure

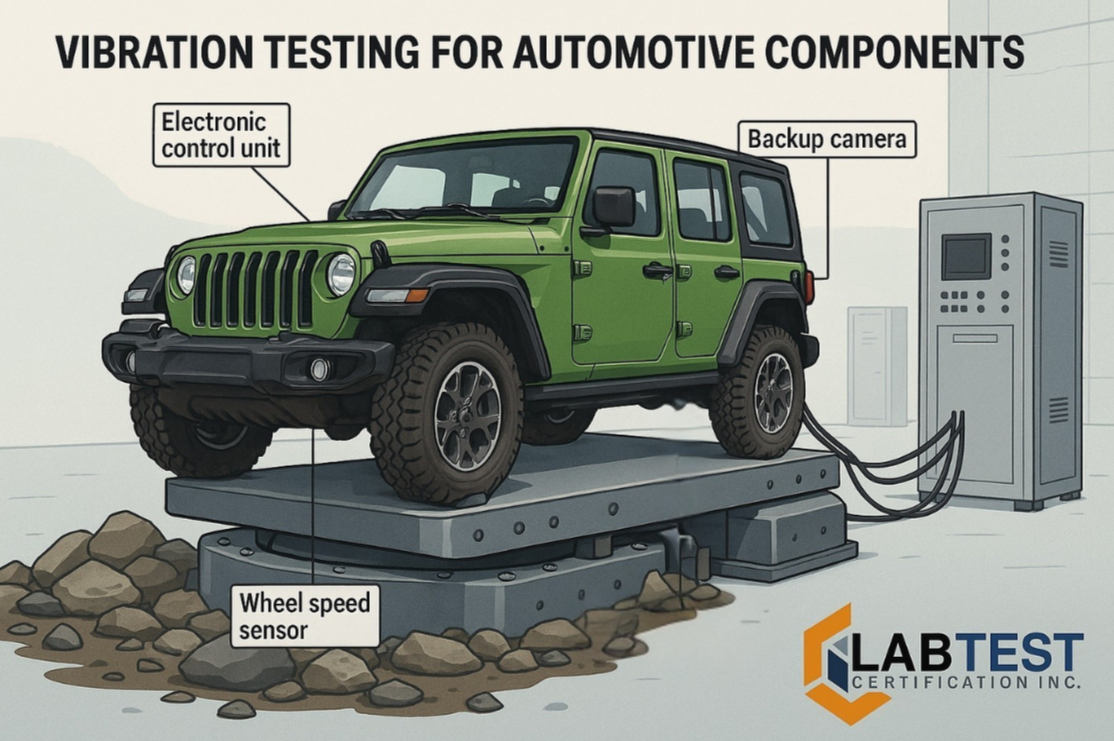

Today’s vehicles, especially off-road ones, are packed with electronic components: sensors, cameras, ECUs (electronic control units), navigation systems, and more. And when you’re bouncing around over rocks and ruts, those components are constantly exposed to intense vibrations.

Now imagine if just one of those components fails. Maybe your ABS system starts acting up, or your backup camera flickers right when you’re reversing near a cliffside trail. Not fun — and definitely not safe.

That’s why vibration testing matters.

What Is Vibration Testing?

In simple terms, vibration testing is a way to simulate the rough, real-life conditions a product might face. For automotive parts, that means mimicking the shaking, bouncing, and jolting that happen during regular driving — and especially during off-road adventures.

By putting components through these tests in a lab, engineers can find weak spots before the parts ever make it into a vehicle.

What it MIL-STD-810?

One of the most respected standards used in vibration testing is MIL-STD-810. Originally developed by the U.S. military, this standard outlines how to test equipment for tough environments, from desert heat to high-altitude cold, and yes, to harsh vibrations.

MIL-STD-810 is a huuuge standard!

We’re talking over 1,000 pages covering dozens of test methods: vibration, temperature, shock, sand and dust, salt fog, humidity, altitude, and more. It’s designed to simulate just about any environmental condition equipment might face, from the desert to the Arctic.

Even though it’s a military standard, many automotive manufacturers use MIL-STD-810 as a benchmark. Why? Because if a component can survive military-level conditions, it’s more than ready for civilian use, even for extreme off-roaders.

A Real-World Example

Let’s go back to that Jeep, shall we? Underneath the rugged frame, there’s a small electronic control unit that manages your vehicle’s traction system. It’s mounted near the rear axle, an area that experiences a lot of vibration.

Let’s use this control unit as an example to explain what happens during a vibration test. During the test, this unit would be strapped to a machine that simulates the same jolts and movements it would experience on a rocky trail, also known as a Vibration Table or Electrodynamic Shaker Table. The test can last anywhere from a few hours to a few days, depending on the manufacturer’s objectives. If the component passes, it means it’s far less likely to fail when you’re 50 kilometres into the wilderness.

Why It Matters

For car manufacturers, vibration testing helps reduce warranty claims and keeps customers safe. For drivers, it means confidence, knowing your vehicle’s components can handle whatever terrain you throw at them.

Whether you’re commuting to work or conquering the backwoods, reliable electronics aren’t a luxury; they’re essential.

So next time you’re revving up for an off-road weekend, remember: a lot of science went into making sure your vehicle can take the heat, the bumps, and the grind. And vibration testing is a big part of that story.

About the Author:

LabTest Certification Inc. is an accredited Testing, Inspection, and Certification Body providing global product approvals for a vast range of product categories. For more information, please visit https://labtestcert.com/

Connect with LabTest Certification: