Solar Modules Under Pressure: What Happens Before They Hit the Roof

Solar Modules Under Pressure: What Happens Before They Hit the Roof

The first thing most people notice about solar panels is their quiet efficiency: sunlight goes in, electricity comes out.

What they don’t see is what those panels have already endured before ever reaching a rooftop or solar field.

Before they harvest light, they’re blasted with it.

Before they generate power, they’re pushed to failure.

Before they’re certified, they’re punished by every element they’re meant to resist.

Reliability in solar pans isn’t just measured by how they perform on a sunny day; it’s also measured by how they survive decades of weather and irradiance.

What “Under Pressure” Really Means

Every certified solar module must prove its safety compliance through testing that replicates years of exposure in just weeks.

Inside climate simulation chambers, panels cycle through:

- Extreme heat and cold to simulate desert days and icy nights.

- Humidity-freeze and damp-heat exposure to test moisture resistance over years of condensation.

- Mechanical load tests that simulate strong updraft winds and snow loads pressing on every frame.

- Hail impact testing may be included using ice spheres shot at over 20 m/s to mimic real storm damage.

- UV radiation aging that exposes modules to more sunlight in weeks than some climates do in a decade.

And while panels endure those environmental stresses, electrical endurance testing evaluates how current, voltage, and insulation hold up under continuous operation.

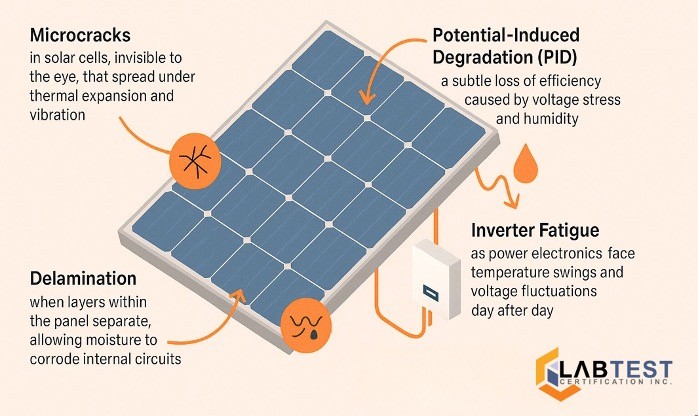

The Invisible Enemies: Failures You Don’t See Coming

What certification testing often reveals are not catastrophic breaks but microscopic flaws that grow silently over time:

- Microcracks in solar cells, invisible to the eye, that spread under thermal expansion and vibration.

- Potential-Induced Degradation (PID): A subtle loss of efficiency caused by voltage stress and humidity, slowly draining panel output.

- Delamination: When layers within the panel separate, letting in moisture that corrodes internal circuits.

- Inverter fatigue: Components stressed by voltage fluctuations and heat cycles, eventually altering power output or safety response.

These are not faults caught by simple performance tests.

They’re uncovered only through certification-grade evaluations designed to push products beyond their normal limits.

Beyond Efficiency: The Real Purpose of Certification

Solar testing and certification standards like IEC 61215, IEC 61730 and UL 2703 ensure that every component from the photovoltaic cell to the mounting hardware performs safely and predictably.

These tests verify not only efficiency, but:

- Electrical insulation and fire safety under fault conditions.

- Grounding and isolation resistance to prevent shocks and arc faults.

- Mechanical durability for rooftop and structural mounting.

For manufacturers, certification is the language of market access.

For installers, it’s the difference between approval and rejection during permitting.

For consumers, it’s silent assurance that their solar investment will keep generating power safely, season after season.

And for governments and utilities, certification is what separates verified renewable power from potential risk, it’s what enables rebate eligibility, net metering, and connection to public infrastructure.

When the Sun Becomes the Stress Test

In one notable project, a large-scale solar farm began seeing unexpected power losses within its first year. The panels looked pristine, but infrared imaging revealed “hot spots”, local areas where minor cell cracks caused resistive heating.

What caused them? Improper mounting pressure during installation.

And what exposed them? Certification-grade thermal cycling and electroluminescence (EL) imaging, the same tests that would have caught the weakness before deployment.

The lesson was clear:

Every watt lost in the field is a test that could have been passed in the lab.

Beyond the Test

Testing doesn’t end with compliance; it defines the product’s lifespan. Each cycle of heat, light, and load maps how materials age, how insulation holds, and where mechanical stress accumulates. Certification translates those findings into data-driven confidence: knowing exactly how a panel will perform after ten years, not just on day one.