Division or Zone? That’s The Question.

Division or Zone? That’s The Question.

It’s a question that sounds simple and technical and in reality, it is simple, provided it’s asked at the right time.

The choice between Division and Zone classification is not something discovered late in the process; it’s a foundational decision made at the very beginning of an equipment’s design and compliance journey.

Is this equipment marked for Division or for Zone?

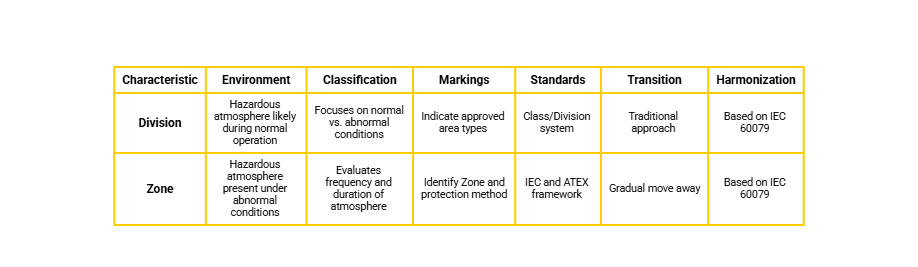

The distinction isn’t about whether a product is suitable for use in a hazardous location. It’s about how that hazardous location is classified, which standards apply, and whether the equipment’s design, testing, and markings align with the applicable code requirements for the intended market and installation. The difference may appear subtle on paper, but it directly affects certification pathways, markings, acceptance by authorities, and ultimately, where and how the equipment can be used.

Two Systems, One Environment

In North America, hazardous environments have historically been described using the Class/Division system. Under this approach, equipment markings indicate the types of areas the product is approved for:

- Division 1: for locations where a hazardous atmosphere is likely to be present during normal operation, and

- Division 2: for locations where it might be present under abnormal conditions.[EN2]

The Zone system, rooted in the international IEC and ATEX framework, approaches the same risk differently. Instead of focusing on “normal” versus “abnormal” conditions, it evaluates how often and how long an explosive atmosphere is likely to exist. Equipment markings identify both the Zone and the method of protection used to prevent ignition.

Both systems describe the same environment. They simply speak different regulatory languages and those languages are no longer evolving in parallel.

The Shift That’s Been Quietly Changing Expectations

What many manufacturers don’t realize is that this isn’t just a technical debate, it’s a regulatory transition already underway.

In Canada, the Canadian Electrical Code (CSA C22.1) mandates compliance markings for all hazardous location equipment. The newer editions of the Code require equipment to be marked for Zones and methods of protection, signaling a gradual move away from the traditional Class/Division approach.

In the United States, the National Electrical Code has followed a similar path. While Class/Division markings are still widely recognized, the NEC has increasingly adopted Zone-based classification and methods of protection, reflecting alignment with international practices.

As a result, what used to be an either/or choice is becoming a moving target.

Why Standards Matter More Than Markings Alone

This shift is closely tied to the adoption of the IEC 60079 series of standards.

Both Canada and the United States are members of the IECEx Scheme, and both have adopted IEC 60079 with country-specific national deviations. In practice, this means manufacturers can often evaluate products to a single IEC-based test program, while still addressing regional requirements.

In Canada, hazardous location products are evaluated to CSA standards derived from IEC 60079. In the United States, evaluations are conducted to ISA, UL, and/or FM standards, which are also based on the same IEC framework.

These standards are steadily harmonizing requirements with the goal of reducing duplicate testing and helping manufacturers meet multiple market requirements more efficiently.

But harmonization doesn’t mean uniform interpretation, and that’s where problems still arise.

Why This Still Shows Up Late

Despite this alignment, classification questions often surface late in a project.

By the time equipment reaches installation or inspection, decisions about markings, standards, and protection concepts have already been locked in. If those decisions don’t match how a jurisdiction or inspector interprets the hazardous area classification, even compliant equipment can face delays.

Where LabTest Fits In

At LabTest Certification, through our North American hazardous location approvals, including NRTL certification for both Class/Division and Zone-based equipment, we help manufacturers ensure their products are evaluated and marked in ways that align with how they will be installed and inspected.

It’s not about choosing one system over another, but about understanding the implications early enough to avoid late-stage delays.

The Real Takeaway

Hazardous location equipment compliance rarely fails because risk wasn’t considered.

It falters when classification assumptions go unexamined.

Division and Zone systems describe the same environments through different lenses. Knowing which lens will be applied and where could be the difference between a smooth installation and an unexpected delay.