H.A.L.T. (Highly Accelerated Life Testing) is a common and well-known procedure in electronics’ manufacturing, such as: medical devices, computers, military equipment, etc.

As reliable products are the key to a successful business in the manufacturing industry, more and more manufacturers are looking to expose their prototype units to a H.A.L.T. (Highly Accelerated Life Testing) process during designing or procurement phase, immediately before the actual production phase begins, in order to find and expose the weaknesses and their root causes related to the products they design.

This way, designers, engineers and developers are able to enhance the final product, by pushing its destruct limits beyond the operating specifications.

By creating a tailored H.A.L.T. test plan for their products and working closely with a testing laboratory, manufacturers are more likely to end up with a more reliable and mechanically stable unit, and less likely to experience too many warranty claims in the future.

Experienced testing laboratories, with qualified technical personnel, can provide assistance to manufacturers to create the appropriate H.A.L.T. procedures for their products, based on the end application, technical requirements, and the environment in which the products will be operating.

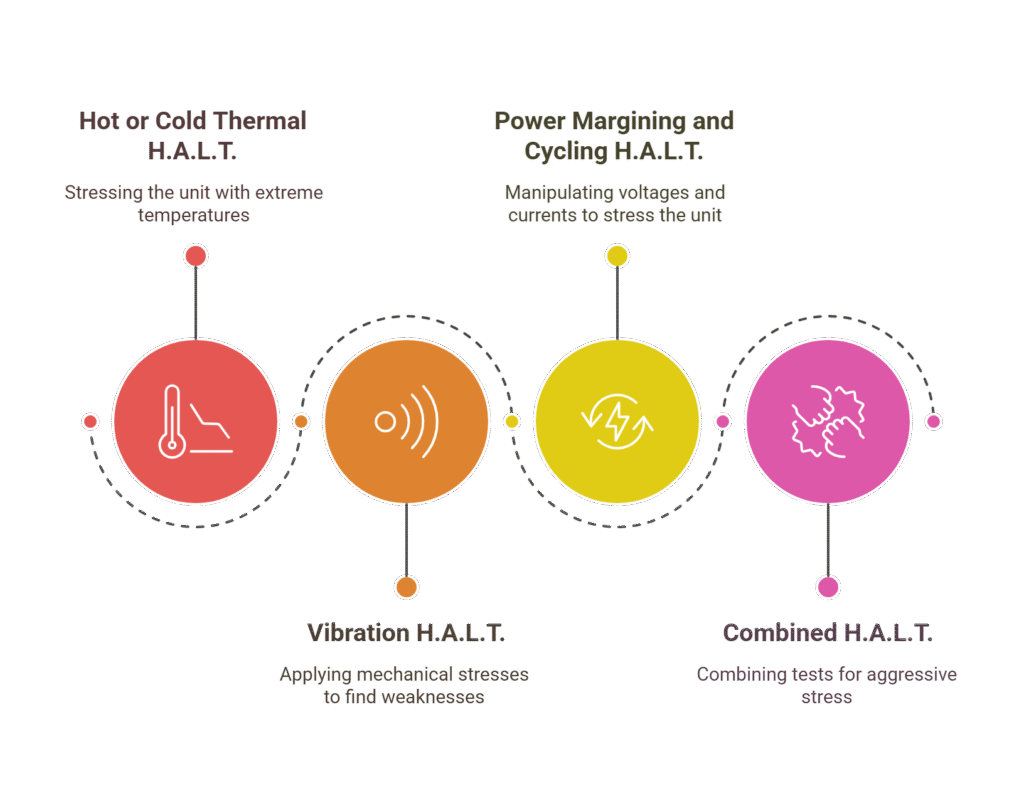

The most common tests used in a H.A.L.T. process are:

-

Hot or Cold Thermal H.A.L.T. procedures

– the purpose of these procedures is to stress the unit and trigger operational malfunctions by pushing the environment temperature levels beyond its normal operation. Duration of these tests could be increased depending on the requirements, as well as the temperature changing rates can be manipulated in ways that will create big thermal fluctuations, accelerating the aging process. Also as part of these procedures, combinations between cold, hot and humidity tests can be performed as Thermal Shock cycles;

-

Vibration H.A.L.T. procedure

Combination of mechanical stresses induced by Random Vibration profiles and Shock Tests. The vibration profiles for this procedure are created and have the intention of finding physical durability limits and weaknesses, in order to improve its mechanical integrity;

-

Power Margining and Power Cycling H.A.L.T. procedures

Specific electrical and safety tests, developed to stress the unit by applying different programs and cycles, manipulating voltages and currents beyond its normal operational ratings;

-

Combined H.A.L.T. procedure

The most aggressive process related to the R&D phase and can be any combination of the above test procedures. This is the best way to go above and beyond the worst-case scenario.

In essence, H.A.L.T. takes testing to a higher level, beyond any qualification ratings or pass/fail criteria given by standards. The actual scope of it, is to simulate wear and tear of a product over the years, in just a few days or hours.

When this is the case, failure is not a surprise anymore, but almost an expectation.

Implementation Process

-

Test Planning

Define stress levels based on:-

Product application (e.g., implantable medical devices)

-

Environmental requirements (MIL-STD-810, IEC 60068)

-

Failure history of previous designs

-

-

Failure Analysis

Identify root causes using:-

Electrical signature analysis

-

X-ray/CT scanning of assemblies

-

-

Design Validation

Verify fixes through:-

Comparative H.A.L.T. rounds

-

Correlation with field data

-

Industry Applications

| Sector | Critical Findings | Standards |

|---|---|---|

| Medical Devices | Battery connector separation | ISO 13485 |

| Automotive | Solder joint fatigue | AEC-Q200 |

| Aerospace | Conformal coating delamination | DO-160 |

Data-Backed Results

-

Medical device manufacturers report 60-80% reduction in warranty claims after H.A.L.T. implementation

-

Typical test duration: 5-7 days simulates 5+ years of operation

Testing Standards Reference

NASA reliability handbook:

NASA-HDBK-7005

Laboratory Requirements

Accredited H.A.L.T. facilities provide:

-

Thermal chambers with ≥70°C/minute transition rates

-

Power margining equipment (±200V capacity)

Failure Analysis Techniques

-

Scanning electron microscopy (SEM)

-

Fourier-transform infrared spectroscopy (FTIR)

Implementation Case Study

An industrial sensor manufacturer:

-

Discovered capacitor electrolyte leakage during thermal cycling

-

Redesigned PCB layout with 50% greater clearance

-

Achieved zero field failures in 24 months post-redesign