The Weakest Link in EV Charging Isn’t the Battery – It’s the Plug Between Them

The Weakest Link in EV Charging Isn’t the Battery – It’s the Plug Between Them

So much attention in electric vehicles goes to the battery pack and for good reason. It’s expensive, densely packed with energy, and historically associated with headline-grabbing incidents. But in real world performance and safety evaluation; the charging interface, the cable, plug, inlet, and associated protective systems often shows issues before the battery ever exhibits trouble.

This isn’t about sensational failures. It’s about physics, connection integrity, and environmental exposure that only show up once a product hits the real world.

Where Most Failures Begin

When an EV is plugged in, power flows from the grid to the vehicle through a conductor and connector system. You’d think that’s straightforward but it’s not:

🔌 High Contact Heating The point where the charger’s pins meet the vehicle inlet is a place where current density spikes, and even microscopic variations in contact resistance can cause significant heating over repeated use.

⚙️ Mechanical Wear Over Mating Cycles Every connection and disconnection wears down pin plating and engagement surfaces. Over time, this increases resistance and heat long before any battery issues appear.

🌧️ Environmental Exposure Rain, dust, sunlight, and vibration all influence connector performance. A sealed battery enclosure doesn’t help if the connector seals fail first.

⚡ Protective Systems Interaction Modern chargers implement safety measures like ground fault detection, residual current devices, and protective disconnects but these only work if the charging interface behaves predictably under stress.

These are practical failure paths, not hypothetical ones.

Standards That Reveal the Weak Spots

Charging systems aren’t just tested for “does it charge”, they’re evaluated against specific safety and performance requirements that anticipate real use and mis-use.

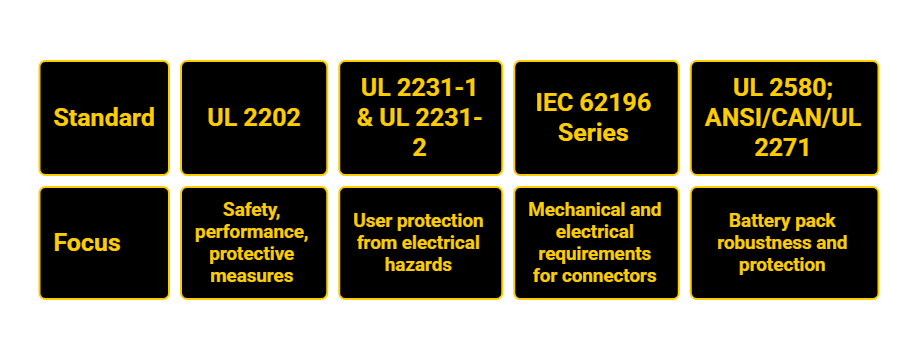

🔌 UL 2202 — Electric Vehicle (EV) Charging System Equipment

This standard defines requirements for safety, performance, and protective measures for AC and DC EV charging systems, including connectors, enclosures, wiring, and protective features.

⚡ UL 2231-1 & UL 2231-2 — Personnel Protection Systems for EV Supply Circuits

These standards focus on how charging interface systems protect users from electrical shock, ground faults, and hazardous leakage conditions in EV charging circuits.

🛠 Connector & Inlet Standards (IEC 62196 Series)

Internationally, plugs and inlets for EV charging are governed by IEC 62196, which defines mechanical and electrical requirements for connectors and inlets for AC and DC charging environments including dimensional compatibility and thermal stress behavior.

🔋 Battery Standards (UL 2580; ANSI/CAN/UL 2271)

Although batteries remain a central safety focus, these standards ensure battery packs used in vehicles are robust, mechanically sound, and electrically protected, complementing charger safety.

Taken together, these standards go far beyond simple current flow, they define how the entire interface behaves under electrical, mechanical, thermal, and environmental stress.

What Lab Testing Actually Uncovers

In controlled lab environments, these evaluations look at:

- Thermal rise under rated current cycles — does temperature stay within safe limits after thousands of connections?

- Contact resistance changes over time — does wear degrade performance?

- Ingress protection and seal integrity — can moisture or contaminants get in?

- Shock and vibration effects — does real-world movement loosen or misalign connections?

- Protective device response — do safety systems act quickly and consistently when faults occur?

A charger can “work” in simple plug-in tests but what happens after 500, 2,000, or 5,000 plug cycles? That’s where meaningful data emerges.

Real World Isn’t As Clean As the Lab

Charging equipment isn’t used in controlled environments, it lives outdoors, sees rapid temperature changes, gets exposed to dust, moisture, road salt, and vibration, and is handled by thousands of different users who don’t always seat a connector perfectly or treat it gently. Over time, these everyday factors compound.

What we often see is that charging cables and connectors begin to degrade quietly under this cumulative stress, long before the vehicle’s battery system shows any sign of trouble. It’s not a dramatic failure, it’sgradual wear, rising resistance, subtle heating, and performance drift. And those are exactly the kinds of issues that matter most once equipment leaves the lab and enters daily use.

The Takeaway

Batteries are critical but connectors are where everyday safety and reliability are tested most. Ensuring EV charging systems are evaluated against the right standards and that those standards reflect real-world behaviors helps manufacturers build products that deliver not just power, but consistent, dependable performance.

If you’d like to explore testing and certification for EV charging systems or related components, we’re here to help. Request a free quote today : rfq@labtestcert.com