Why the Holidays Are the Perfect Storm When It Comes To Product Performance

Why the Holidays Are the Perfect Storm When It Comes To Product Performance

For most people, Christmas morning feels calm and familiar. Lights turn on, heating runs steadily, appliances work a little harder than usual. Nothing feels out of the ordinary.

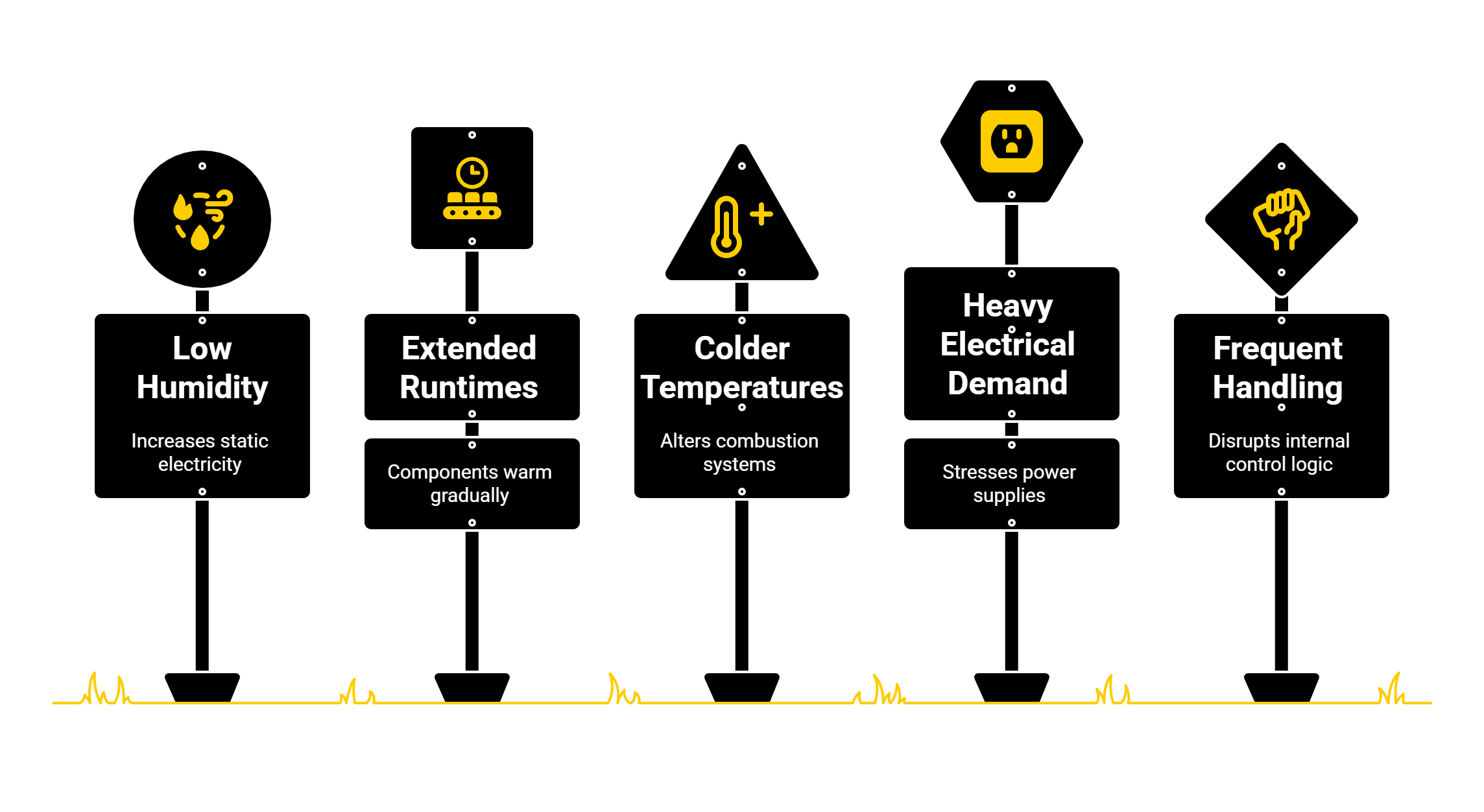

From a product-performance perspective, however, December creates a combination of conditions that rarely exist together at any other time of year: the Perfect Storm[EN1] . Low indoor humidity, extended runtimes, colder ambient temperatures, sealed living spaces, heavier electrical demand, and constant human interaction all happen at once.

Individually, none of these are unusual. Together, they create one of the most demanding operating environments products will experience all year.

When the Environment Becomes the Variable

Holiday safety conversations usually focus on how products are used. But during winter, the environment itself becomes a major factor in how products behave.

For example, indoor heating dries the air. As humidity drops, static electricity becomes more frequent and less predictable. These events are often too small to notice but inside electronics, they can momentarily disrupt power flow or confuse internal control logic, especially when devices are running continuously. This is why tests like Electrostatic Discharge (ESD) are critical for equipment that will experience these kinds of scenarios. The testing verifies that products will remain stable and recover properly when these events occur.

Why Time Matters More Than Load

During the holidays, many products don’t work harder, they work longer.

Decorative lighting stays on for hours at a stretch. Fireplaces and heaters operate daily. Kitchens see near-continuous appliance use. Chargers stay plugged in around the clock.

What prolonged operation reveals is different from what short bursts ever show. Components warm gradually. Materials respond slowly. Small tolerances begin to drift.

Issues tied to time and temperature rarely announce themselves immediately. They surface quietly, often after days of normal-looking operation — which is why winter tends to reveal them first.

Cold air changes how combustion systems behave

In winter, colder, denser air and more tightly sealed buildings alter pressure relationships around gas-fired and vented products. These shifts can affect ignition stability, draft strength, and exhaust flow even when the product is properly installed and operating as designed.

Why winter is a new device’s first real test

It’s common for new electronics to show odd behaviour during the holidays. That’s often assumed to be a quality issue, but in many cases, it’s seasonal.

December is usually the first time a device experiences:

- Colder storage and startup conditions

- Dry indoor air

- Long charging cycles

- Heavy network traffic

- Frequent handling and relocation

Batteries, for example, respond differently when cold. Power supplies behave differently under extended use. Static becomes part of daily interaction.

When a brand-new device behaves unexpectedly in December, it’s rarely defective. More often, it’s meeting a combination of stresses it hasn’t faced before.

Holiday’s final verdict

Winter doesn’t introduce new risks. It compresses familiar ones.

Dryness, cold, time, load, airflow changes, and human behaviour overlap in ways that don’t happen in other seasons. December quietly tests how products behave when those factors align.

This is why the holiday season is such a useful reference point for understanding real-world performance not because it’s extreme, but because it’s realistic.

The Takeaway

Christmas doesn’t change how products are designed.

It reveals how they perform when everyday stresses coincide.

For consumers, the season feels effortless.

For engineers and evaluators, it shows exactly where margins matter.

And that’s why winter remains one of the most revealing environments products will ever face not as an emergency, but as a measure of how well they were built to begin with.