Testing products for EMC compliance | 5 common issues

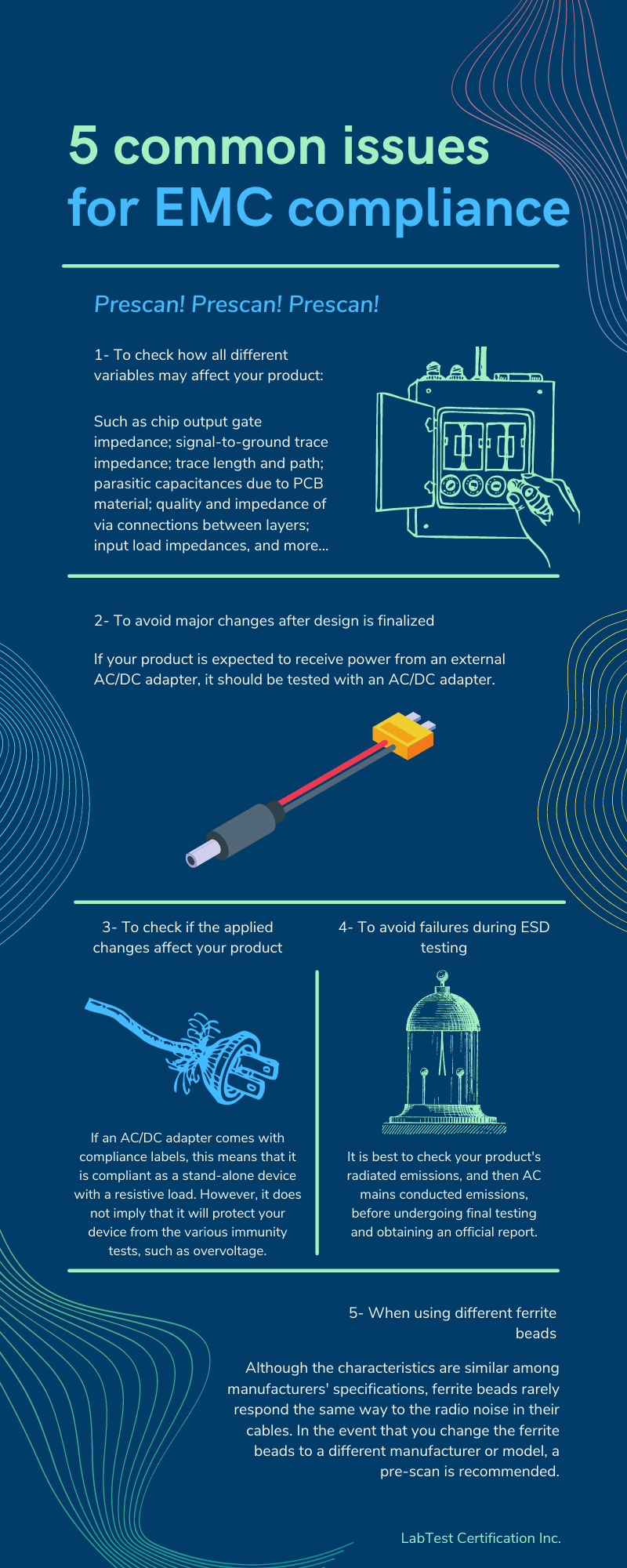

When asking EMC engineers what the most common challenges that they face are, when testing products for compliance with EMC requirements, they bring up five main trouble areas that seem to be a pattern.

1. Assuming your product will pass

In Electromagnetic Compatibility (EMC) testing, unless the latest EMC modeling tools are used for circuitry and assembly, it’s often not simple for engineers to account for all variables, such as chip output gate impedance; signal-to-ground trace impedance; trace length and path; parasitic capacitances due to PCB material; quality and impedance of via connections between layers; input load impedances, and more.

Therefore, it is better to pre-scan the entire product and determine its status rather than assuming “it should be good enough”.

The last thing you want is to find out that you have to modify the circuit, when you’re about to ship your product out.

2. AC Mains Conductive Emissions: here’s the thing

If your product is expected to receive power from an external AC/DC adapter, it should be tested with an AC/DC adapter.

If your product is expected to receive power from an external AC/DC adapter, it should be tested with an AC/DC adapter. This applies to both Emissions and Immunity testing. This is a requirement of most standards, such as FCC Part 15/B, CISPR 32 and CISPR 35.

The reason for this requirement is that AC/DC power adapters are normally expected to be part of your product.

In situations where DC power only is specified, the product is normally installed into a DC power network, which will have its own DC mains conducted emission requirements.

3. Caution about AC/DC Power Adapters

Although AC/DC adapters have compliance labels, this does not guarantee that the product will pass EMC testing.

If an AC/DC adapter comes with compliance labels, this means that it is compliant as a stand-alone device with a resistive load. However, it does not imply that it will protect your device from the various immunity tests, such as overvoltage.

It also does not mean that it has the necessary filtering to protect the world from any emissions that may be present at the DC power port of your product.

Also note that the product’s approved bill of materials should record the manufacturer, model number, and revision number. Pay attention to products where the “Revision” number has changed.

If the revision number has changed, you should plan to perform a new pre-scan to check if there was a change that affected your products. Often, the changes may indicate a change in components that reduce the filtering of/for your product.

4. Don’t assume that your product will pass EMC testing the first time

From experience, most products do not pass Emissions testing the first time. It is best to check your product’s radiated emissions, and then AC mains conducted emissions, before undergoing final testing and obtaining an official report.

If your product has a headphone audio circuit, you should be prepared to know how much audio interference you will allow to come from your product during RF immunity testing.

Also keep in mind that many products have been known to fail Electro-static Discharge (ESD) testing, so pre-scanning for ESD is also a good idea.

5. Don’t assume that all ferrite beads are the same

Although the characteristics are similar among manufacturers’ specifications, ferrite beads rarely respond the same way to the radio noise in their cables. In the event that you change the ferrite beads to a different manufacturer or model, a pre-scan is recommended.

The above five points all seem to share one main advice for manufacturers, which is to have a third-party EMC lab pre-scan the product before submitting it for full compliance testing, as this will save time and money, and avoid having to make major changes once the product design is already finalized.

For any questions about EMC testing for north American or international markets, you can contact LabTest Certification at info@labtestcert.com or call 1-855-346-0444.