What does Fenestration mean?

Fenestration refers to an opening in the seal of a building, such as windows, doors, and skylights. These additions will enhance the overall indoor environment by allowing light in.

BUT they will also allow for the possibility of air, and water to enter the building! Therefore, it is important to have fenestration testing to ensure systems meet North American standards. This will increase comfort and best of all, it can save you money by improving the thermal performance on windows.

Building Codes and Standards

All products placed and sold on the market are regulated one way or another. Fenestration products are regulated by Building Codes and by Energy Efficiency Acts.

These regulations have led us to a standard testing for Fenestration in North America (North American Fenestration Standard – NAFS). This is a ‘harmonized standard’ for Canada and the United States. It roots back to three older standards, CSA A440 (Canadian standards Association), AAMA 101 (American Architectural Manufacturers Association) and WDMA 1.S.2 (Window and Door Manufacturers Association), as well as in Canada, NAFS must also comply to the Canadian Supplement CSA A440S1-09.

A Closer Look at Testing

Fenestration testing can be broken into two parts: Physical tests and Energy Efficiency tests.

Fenestration testing can be broken into two parts: Physical tests and Energy Efficiency tests.

The Physical portion of NAFS includes three main tests: Structural, Water Penetration, and Air Leakage (infiltration and exfiltration), along with a series of other tests like Operating force, Uniform load deflection, and more.

Physical Testing provides the client with a Performance Class (R, LC, CW, AW) and Performance Grade (PG) for fenestration products.

To be rated under the specified class, each of the Performance Classes have a minimum gateway performance grade and size that are needed to be achieved by the system. Where Performance Grade (PG) is a two-digit number, the lowest value is PG15, this goes up by multiples of 5 reaching a maximum of 100 for all classes, except for AW for which there is no limit for the PG.

NAFS Testing

NAFS applies to a variety of more than 40 different operating and fixed systems for new constructions, as well as replacement fenestration systems.

All fenestration systems tested must be specified in the Product Type section of the standard, for some systems like interior windows/doors, curtain walls and commercial entrance systems do not comply.

When testing a system, it is important to note that a larger system in size (both width and height) will qualify a smaller version of the same Product Type, with identical Bill of Materials and similar cross sections, without the need to have it tested.

What is a “Mullion”?

NAFS does not solely test Windows and Doors, but also the mullions that connect them.

A “mullion” is a structural element that forms a division between two or more units of a fenestration system, and its primary purpose is to create a stronger connection between the systems forming a Composite unit or a Combination assembly.

Similarly to windows and doors, once a Mullion is tested, it will qualify mullions in similar units or assemblies with equal or smaller spans and less supported mass.

Energy Efficiency Testing

We talked about the physical testing that needs to be applied to a system, but how do we find out how Energy Efficient the system is? This is where Energy Efficiency testing comes in.

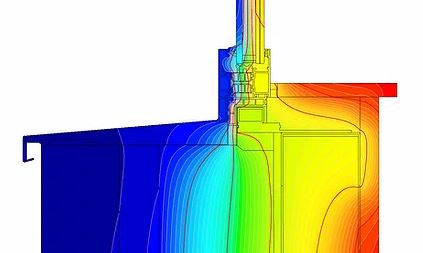

This test consists of a process called Thermal Modeling. Thermal modeling is commonly done by using a computer simulation program that displays how a system will function thermally.

Common programs used in the industry are “Therm” and “Window”, which were both developed by NFRC and LBNL and comply with CSA-A440.2 and NFRC 100.

Thermal Modeling

Thermal Modeling provides the overall coefficient of heat transfer (U-factor), the Solar Heat Gain Coefficient Visible Transmittance, Energy Rating (requirement from CSA A440.2), and the Condensation Resistance (requirement from NFRC 100). U-factor is the most looked at value, for it is the mean value that will determine how energy efficient a window is.

The lower the U-Factor, the more energy efficient the system is. The Solar Heat Gain Coefficient can be looked at as free energy, as it determines the heat that will come in, through the window, and that will stay in.

This is great during the winter but could become a problem during hot summers.

Once Physical and Energy Efficiency tests has been completed, results can be used for R&D purposes or toward Certification. Each municipal jurisdiction has different requirements for the ratings of fenestration systems.

Enforcing fenestration testing as a requirement for manufacturers is a way to help the jurisdictions achieve their energy efficiency goals.

For inquiries about Fenestration or Building Materials in general

please contact LabTest Certification at info@labtestcert.com

and one of our representatives will be happy to assist you.