When Hot Meets Cold: Why Thermal Shock Testing Could Save Your Product

When Hot Meets Cold: Why Thermal Shock Testing Could Save Your Product

Ever launched a product that worked flawlessly in testing only to fail in the field? You’re not alone. From aerospace systems to automotive electronics, unexpected thermal failures cost companies time, money, and reputation. One of the most overlooked culprits? Thermal cycling.

That’s where Thermal Shock Testing comes in, powerfully protecting products before things go wrong.

What Is Thermal Shock Testing?

Thermal Shock Testing subjects products to rapid temperature transitions between extreme highs and lows. Think: -65°C to +180°C in under 20 seconds. It’s like taking your device from the Sahara to the Arctic in the blink of an eye and watching what happens.

Why? Because materials expand and contract differently. When components made of plastics, metals, solders, or composites are exposed to fast and repeated temperature shifts, the stress builds. Without this test, you won’t know if the internal connections hold or crack under pressure … until your customer tells you.

Why Should You Care?

In the real world, things heat up, cool down, and don’t follow a script; thermal shock can be a silent killer. These kinds of failures are notoriously hard to catch on the bench, and even harder to diagnose once they show up months later in the field.

Common consequences of skipping thermal shock testing:

- Microcracks in solder joints or circuit boards

- Seal failures

- Warping of enclosures or misalignment of internal parts

- Loss of calibration or reliability over time

Who Needs This?

Thermal Shock Testing is required in many standards for:

- Semiconductors & electronics

- Automotive components

- Military and aerospace systems

- Space technologies

But it’s not just about meeting necessary standards. Even if your product isn’t required to undergo this test, doing it early in the R&D stage could:

- Prevent warranty claims

- Build customer trust

- Improve product life span

- Avoid embarrassing field failures

How It Works

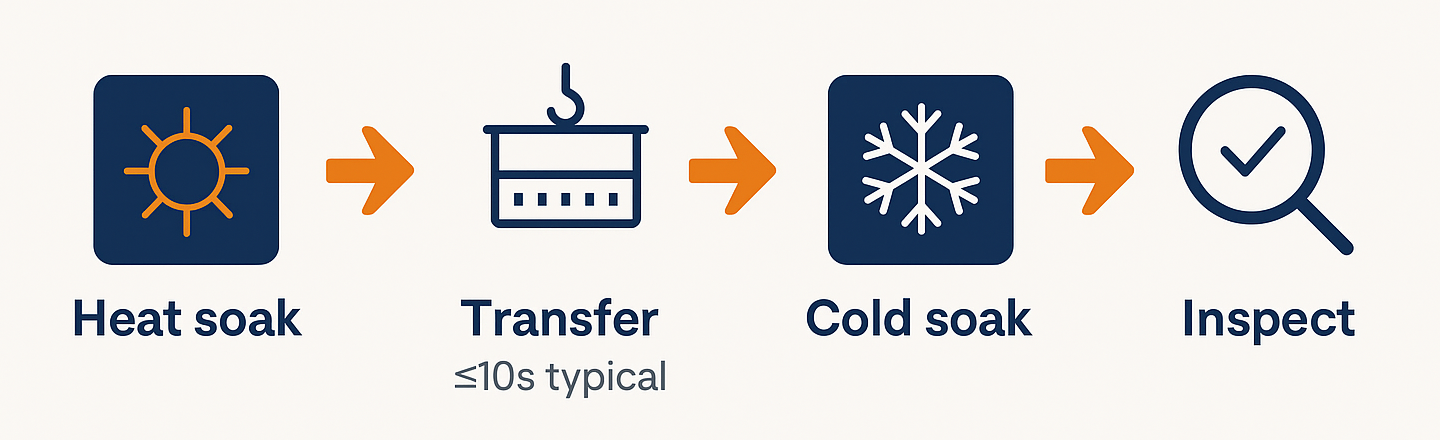

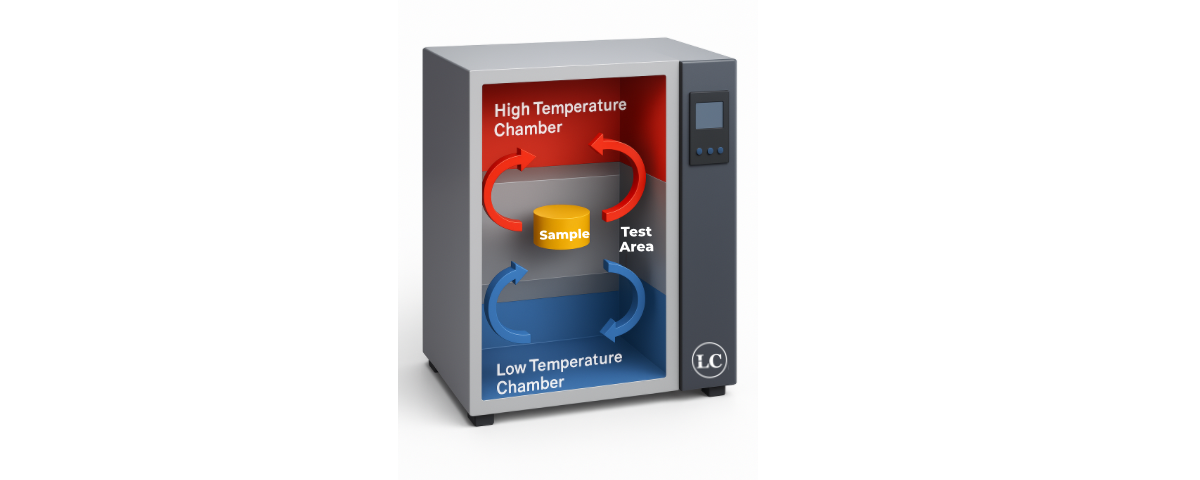

Here’s a visual overview of how the Thermal Shock Test Chamber operates:

At LabTest Certification, our chambers transition between environments in under 20 seconds, delivering shock rates of up to 500°C per minute. With a temperature range from -65°C to +180°C, we simulate harsh real-world conditions.

We don’t just run standard cycles; we can also accommodate custom R&D programs and mixed-environmental testing, even when others can’t.

Benefits of Working with Us

Why choose LabTest for your thermal shock testing needs?

- Faster lead and turnaround times

- Support for R&D and custom setups

- No long queues or rejections for complex requests

- Collaborative team ready to adapt to your testing needs

We don’t just run tests, we work with you to make sure your product is ready for the real world.

About the Author:

LabTest Certification Inc. is an accredited Testing, Inspection, and Certification Body providing global product approvals for a vast range of product categories. For more information, please visit https://labtestcert.com/