Automotive Vibration Testing: Validating Component Durability

Automobile components often experience random excitations from road inputs and periodic vibration from engine firing. Random actions from road inputs like potholes, gravel, uneven pavement, combined with periodic vibrations from engine firing cycles, create complex stress patterns that can lead to premature component failure.

Replicating these factors in a lab, on a shaker bench, can significantly help manufacturers design and validate products to meet durability requirements before costly field failures occur. Through systematic vibration testing, we can identify weak points in component design and verify that products will withstand their intended service life.

There are three vibration testing methodologies: Random Vibration Test, Frequency Sweep Test and Sweep Sine on Random Test.

We offer vibration testing using our single-axis Electrodynamic Shaker System. This system offers a high force and displacement rating, which allows us to test according to the most stringent vibration profiles.

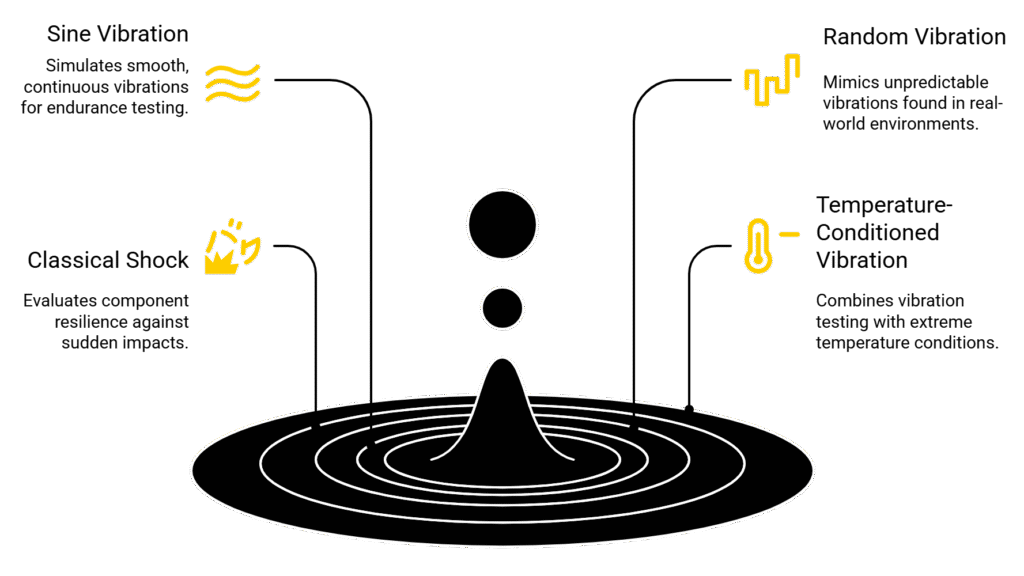

Our Vibration and Shock Testing capabilities include:

-

Sine/Random/Sine-on-Random/Random-on-Random Vibration Testing: We can apply any combination of these waveforms to match your specific application requirements, whether testing follows industry standards like ASTM, ISO, or SAE specifications, or custom profiles developed from field data.

-

Classical Shock Testing: Components must survive sudden impacts from road hazards or accident conditions. Our shock testing capabilities evaluate component response to single-pulse, half-sine, and other shock profiles that simulate these events.

-

Temperature-Conditioned Vibration: Automotive components operate across extreme temperature ranges, from Arctic cold starts to desert heat. Our climate-controlled testing chamber allows us to combine vibration testing with temperature conditioning, revealing failure modes that might not appear under ambient conditions.

Why Automotive Vibration Testing Matters

Component failures in automotive applications carry serious consequences. Safety-critical components like brake systems, steering components, and electronic control modules must maintain functionality throughout the vehicle’s service life. Non-critical failures still result in warranty claims, customer dissatisfaction, and potential recalls.

Vibration testing provides several key benefits:

- Early failure detection: Identify design weaknesses before production

- Validation of design changes: Verify that modifications improve durability

- Qualification to standards: Meet automotive industry specifications and customer requirements

- Service life prediction: Estimate component durability under specific operating conditions

- Cost reduction: Prevent expensive field failures and warranty claims

Testing Process and Standards

Our automotive vibration testing follows established industry standards including SAE, ASTM, and ISO specifications. We can also develop custom test profiles based on field measurements from your specific application.

The testing process typically begins with a review of your component specifications, operating environment, and durability requirements. We then recommend appropriate test methods and develop a test plan that addresses relevant standards while remaining within your project timeline and budget constraints.

Applications Across Automotive Systems

Our vibration testing services support component development across all automotive systems:

- Engine and powertrain components: Validate durability of engine mounts, transmission components, and driveline parts

- Electronic systems: Test control modules, sensors, and wiring harnesses for resistance to vibration-induced failures

- Interior and exterior components: Evaluate dashboard assemblies, trim pieces, and exterior panels for rattle and durability

- Safety systems: Verify performance of airbag sensors, ABS components, and other safety-critical systems

- Alternative fuel systems: Test components for electric, hybrid, and hydrogen fuel cell vehicles

For more info you can visit us on Vibration & Shock Testing services