Shock & Vibe Test | Best available Vibration table in the industry!

This is Hari, Account Manager for the Environmental Testing department at LabTest Certification Inc., Delta BC (Canada). LabTest is a Canadian based Testing, Certification, and Inspection Body accredited to ISO 17025, ISO 17065, and ISO 17020 with facilities in both Canada & the USA.

I am excited to inform you that due to the increasing demand for Vibration testing services, we upgraded our test equipment and increased the capabilities for each of the following:

- Random Vibration testing

- Shock Testing

- Sine Sweep/Resonance Search

- Endurance Vibration Testing

- Conditioned Vibration

Understanding the Tests

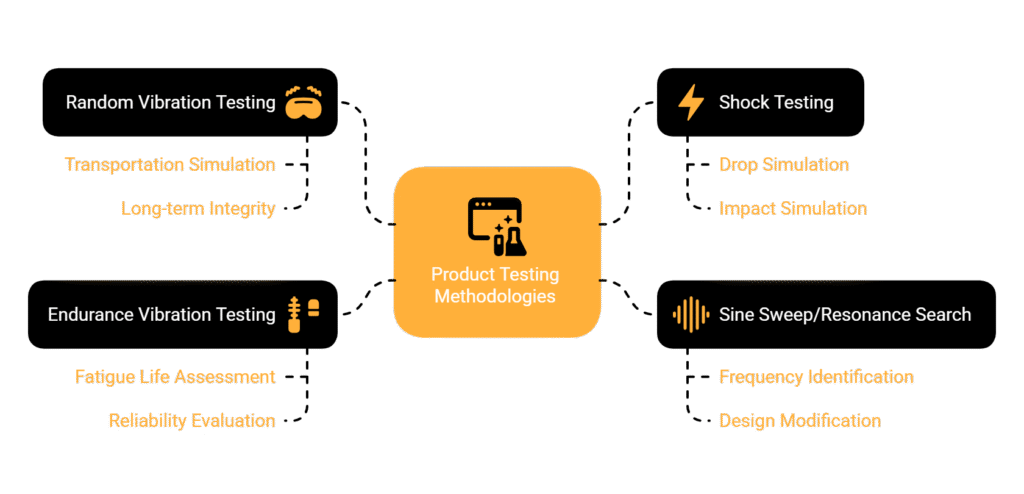

Different stress conditions call for specific test methodologies:

-

Random Vibration Testing: Simulates the unpredictable vibrations encountered during transportation (e.g., truck, air, sea freight) or during the operation of vehicles and machinery. This is essential for evaluating the long-term integrity of a product’s structure and solder joints.

-

Shock Testing: Recreates sudden, high-energy events like drops, impacts, or explosive bursts. This test is critical for verifying that a product can survive accidental handling and remain functional.

-

Sine Sweep/Resonance Search: Identifies a product’s natural resonant frequencies. Discovering these frequencies helps engineers modify designs to avoid them, preventing amplified vibrations that can lead to premature failure.

-

Endurance Vibration Testing: Subjects a product to prolonged vibration profiles to assess its fatigue life and long-term reliability under continuous stress.

Equipment and Capabilities

Our primary tool for these assessments is a 3-axis electrodynamic shaker system. This system is recognized for its performance and can accommodate a diverse array of product sizes and weights.

LabTest 3-axis Electrodynamic Shaker System is one of the best available in the industry and capable of withstanding heavier samples and higher frequency range!

Frequency range: 3 to 4000 Hz

Max payload capacity, vertical orientation: up to 2,400 lbs

Max payload capacity, horizontal orientation: up to 1,000 lbs

Conditioned Vibration

For Conditioned Vibration, our temperature chamber covers a range as wide as -60C to +120C and accommodates for larger samples. A complete cycle between the extreme temperatures can be achieved in less than 7 minutes.

The Purpose of Testing

The primary goal of this testing is risk mitigation. Identifying design flaws, material defects, and assembly weaknesses in a controlled laboratory setting prevents costly field failures, warranty claims, and product recalls. The data collected provides objective evidence of a product’s robustness and reliability for internal validation and client requirements.

LabTest Certification is an accredited Testing Laboratory and Inspection Body. Our accreditations, including ISO 17025, are recognized by national and international organizations, ensuring the integrity and acceptance of your test data.

Begin Your Testing Project

If your product requires validation under mechanical stress conditions, our team is prepared to assist. We can develop a test plan specific to your product’s application and target market.

If you’re looking for a solution to accommodate heavier samples, reach higher frequencies, and require faster temperature cycles than the other available options, Contact Us today!

For any questions or to speak with our Environmental Testing department:

Contact Us at info@labtestcert.com or Call 1-855-346-0444.

We would be very happy to assist!